Rotating Skip Bin

Product Highlights

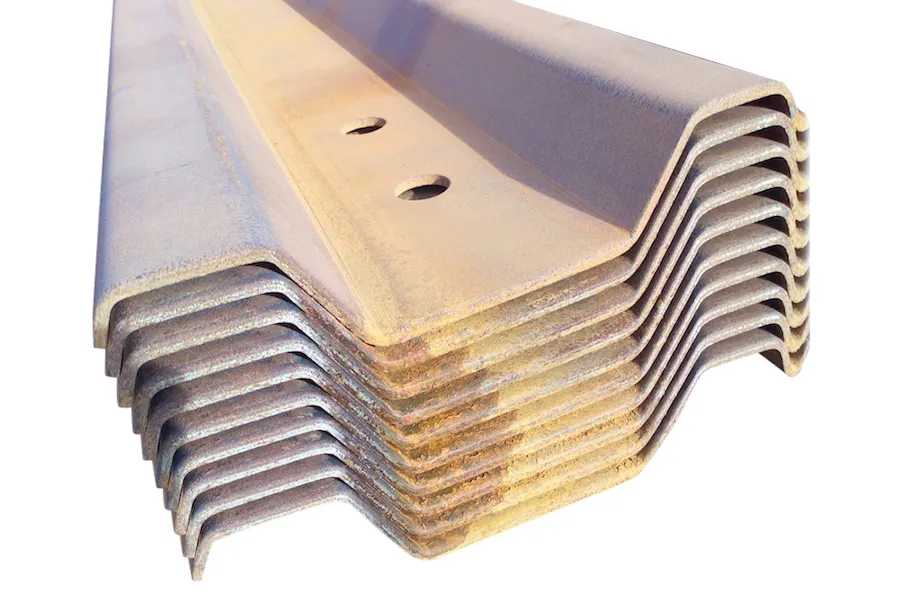

- Heavy-duty build - Constructed from robust steel for long-term durability.

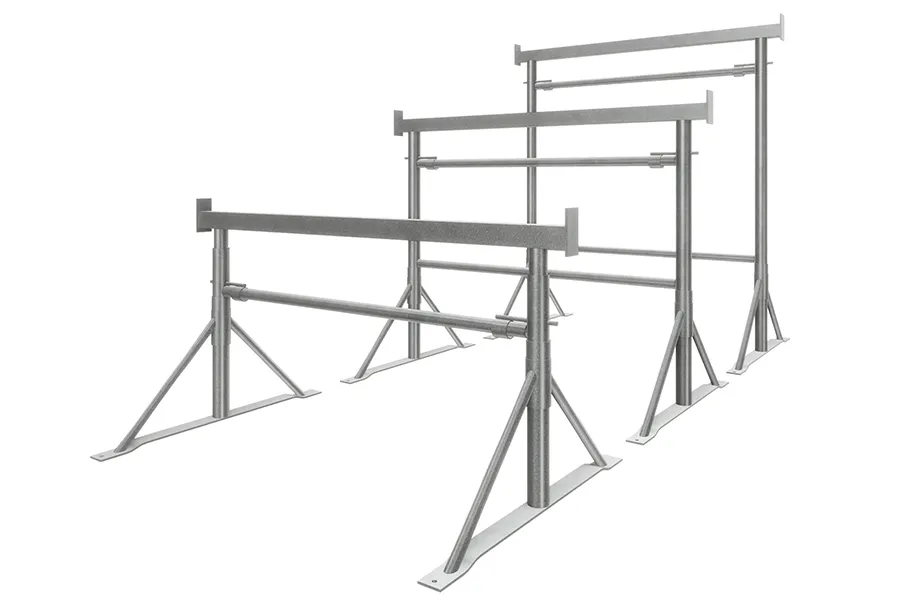

- Forklift integration - Designed with reinforced pockets for secure lifting.

- Controlled rotation - Rotates safely using forklift rotator attachments.

SKU TS1542z

Optimized for efficient waste handling, the Rotating Hopper Bin is ideal for construction, manufacturing, and recycling industries. Built with integrated forklift pockets, it is designed for easy lifting and rotation using forklifts with a rotator attachment, enabling safe and effortless material disposal.

Made from durable steel, it enhances site efficiency while minimizing manual handling risks.

Quickest Available Delivery: Quickest Available Delivery: Up to 10 Working Days

The Rotating Hopper Bin is an essential tool for industries that handle bulk materials and waste. Built for strength and efficiency, the bin rotates forward when the forklift’s rotator attachment turns, allowing materials to be tipped out easily. This feature reduces manual labor, enhancing workplace safety while improving productivity.

Commonly used in construction, demolition, manufacturing, and recycling, these bins streamline material handling by enabling swift disposal of waste, scrap, or bulk materials.

Constructed from high-quality steel, these bins withstand the harshest conditions, making them a long-term investment for businesses. With US manufacturing and fast delivery options, they are readily available to meet industry demands. Whether handling construction debris, industrial waste, or agricultural produce, the Rotating Hopper Bin is the ultimate efficiency booster for material disposal.

Key Features

-

Heavy-duty construction ensures durability in demanding environments.

-

Rotating mechanism allows controlled, effortless material dumping.

-

Forklift-compatible design with built-in pockets for secure lifting.

-

Available in 2 sizes to suit various industrial applications.

-

Manufactured in the USA with fast delivery for minimal downtime.

Designed to simplify heavy-duty waste management, the Rotating Hopper Bin offers a reliable, high-performance solution for a variety of industries.

- Seamless forklift integration – Equipped with reinforced forklift pockets, ensuring stable and secure lifting during operation.

- Controlled rotation – The bin tilts forward when engaged with a forklift rotator, allowing safe, precise material disposal without spillage.

- Heavy-duty build – Made from high-quality steel, ensuring long-lasting performance in demanding industrial environments.

- Versatile applications – Used in construction, recycling, manufacturing, and agricultural industries to manage bulk waste and materials efficiently.

- Labor-saving efficiency – Reduces manual handling risks, speeding up disposal processes and improving overall site safety.

The Rotating Hopper Bin is available in two capacities:

- Small (4409 lbs capacity) – Best suited for medium-scale waste disposal and construction debris.

- Large (6614 lbs capacity) – Ideal for heavy-duty industrial waste and high-volume materials.

For businesses seeking additional waste management solutions, explore our Hopper Light accessory, or our Premium Forklift Self-Dumping Hoppers for alternative options.

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq-usa.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

The rotating dumping hopper from HERMEQ has been designed to deliver both safety and performance in demanding working environments. Its steel construction ensures resistance to heavy impacts, repeated cycles of loading and dumping, and exposure to harsh site conditions. This quality-focused build provides long-term reliability, reducing maintenance needs and lowering lifetime costs for businesses.

Forklift compatibility is central to its design. Reinforced pockets allow forklifts fitted with rotator attachments to engage the hopper securely, providing full control during lifting and dumping operations. This secure connection reduces the risk of accidents and increases operator confidence on busy worksites. Controlled forward rotation helps maintain safety and efficiency by minimizing waste spillage, particularly valuable in recycling and manufacturing plants where precision disposal is critical.

The rotating hopper is available in two capacity options: 4409 lbs and 6614 lbs. The smaller unit offers flexibility for moderate waste volumes, while the larger unit is purpose-built for heavy-duty materials and bulk handling. This scalability makes it suitable for a wide range of projects, from construction and demolition to industrial and agricultural operations.

By integrating rotating hoppers alongside traditional forklift dumping hoppers, businesses can establish a complete waste management solution. While forklift dumping hoppers provide quick self-dumping functionality, the rotating hopper adds control and precision. Together, these tools optimize workflows and ensure that waste removal is handled efficiently in every part of the site.

| Specification | Detail |

|---|---|

| Material | Heavy-duty steel construction |

| Capacities | Available in 4409 lbs and 6614 lbs |

| Operation | Controlled rotation via forklift rotator attachment |

| Applications | Construction, recycling, demolition, manufacturing |

What makes a rotating dumping hopper different from a standard forklift dumping hopper?

The rotating dumping hopper requires a forklift fitted with a rotator attachment, allowing controlled forward dumping. This offers greater precision compared to standard self-dumping hoppers.

What industries use rotating dumping hoppers?

They are widely used in construction, demolition, manufacturing, recycling, and agriculture where bulk waste and materials need safe, efficient disposal.

What capacities are available?

HERMEQ rotating hoppers come in 4409 lbs and 6614 lbs sizes, providing options for both medium and heavy-duty waste management requirements.

How durable is the rotating hopper?

Constructed from reinforced steel, the hopper is built to withstand demanding conditions, offering long-term durability and reliability on industrial sites.

Is delivery available quickly?

Yes, HERMEQ ensures fast US delivery, reducing downtime and keeping projects moving efficiently.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH