Forklift Dumping Hopper

SKU TS1161A

Enhance material transfer efficiency with our durable forklift self-dumping hoppers. Reinforced design, versatile entry bases, and safety features. Quality US manufacturing. OSHA compliant. Available in various colors and sizes.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

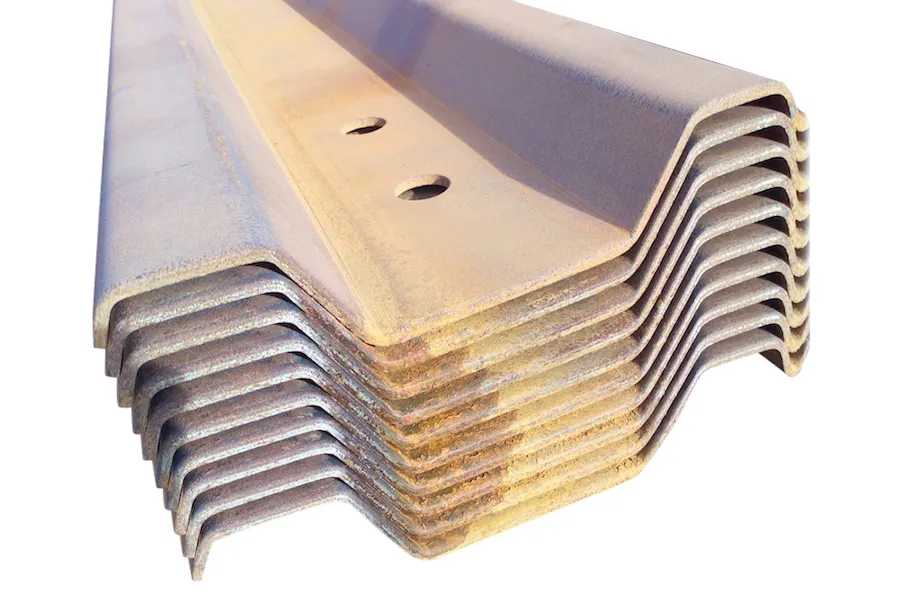

High-quality forklift dumping hoppers, the ultimate solution for efficient material transfer and waste management. Crafted with precision from 11-gauge mild steel plate, our dumping hopper are built to last. We take pride in reinforcing the tops of our bins, going beyond the standard 90-degree angle bend to create a robust and durable D shape return.

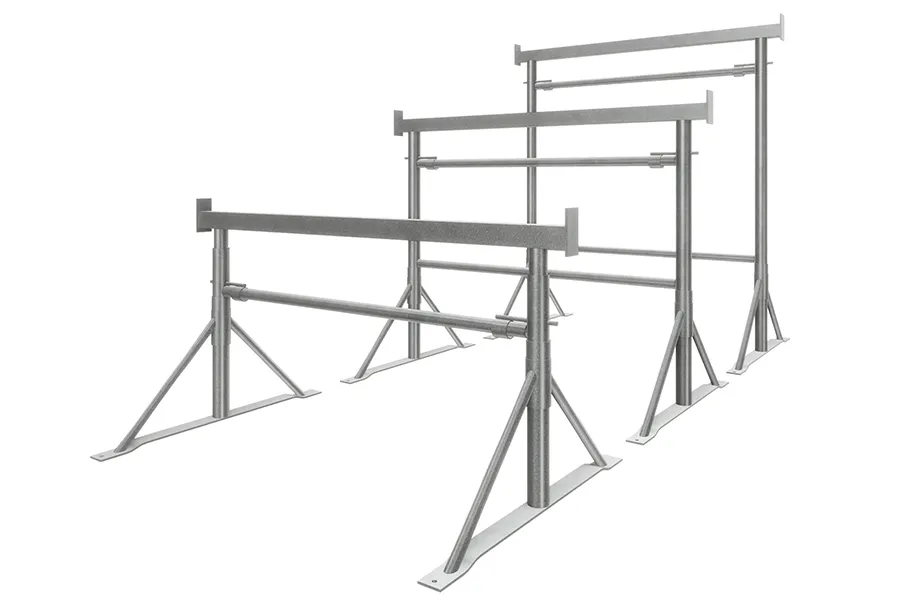

Our forklift dumping hopper feature flexible entry bases, available in 4-way or 2-way entry options. The 4-way entry bases allow for easy lifting from the back or sides, ensuring versatile handling. With user-friendly features like the tip handle for quick release, a self-return and automatic reset mechanism, and a safety retaining chain for secure forklift attachment, our dumping hopper prioritize efficiency and safety in every operation.

We understand the importance of durability and minimizing wear and tear. That's why our forklift dumping hopper fork tunnels are constructed with 5/32" steel and reinforced with a 3/16" steel bar, ensuring longevity and performance. Our bins are designed to accommodate forklift forks, with our Forklift Self Dumping Hopper guides measuring 49.2 in. and our Telehandler Dumping Hopper guides measuring 55.1 in. in length.

Rest assured, our forklift dumping hoppers are manufactured in the United States to the highest quality standards and are OSHA compliant. Experience the long-lasting performance and exceptional value for money that our dumping hoppers provide.

Take advantage of our transportation convenience. Our dumping hoppers can be nested, allowing you to transport multiple bins with the same cost as a single bin. Optimize your transportation expenses and maximize efficiency by purchasing two dumping hoppers at once.

The Forklift Dumping Hopper model gallons equivalents are:

- 750 - 1.00 yard forklift dumping hopper (198 gal)

- 1250 - 1.50 yard forklift dumping hopper (330 gal)

- 1750 - 2.00 yard forklift dumping hopper (462 gal)

|

Capacity (gal) |

Length (in) |

Width (in) |

Height (in) |

Max SWL (lbs) |

Net Weight (lbs) |

|

198 |

61.0 |

49.6 |

33.9 |

4409 |

507 |

|

330 |

69.7 |

52.0 |

43.3 |

4409 |

540 |

|

462 |

72.4 |

52.8 |

50.4 |

4409 |

650 |

- Fork pockets: 6.3 x 3.1 in.

- Fork guides Outer to Outer: 37.8 in.; Inner to Inner: 25.2 in.

HERMEQ offers a wide range of similar products such as our Bins & Stillages, Forklift Dumping Hoppers and Lifting Equipment.

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq-usa.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

| Capacity (gal) | Length (in) | Width (in) | Height (in) | Max SWL (lbs) | Net Weight (lbs) |

| 198 | 61.0 | 49.6 | 33.9 | 4409 | 507 |

| 330 | 69.7 | 52.0 | 43.3 | 4409 | 540 |

| 462 | 72.4 | 52.8 | 50.4 | 4409 | 650 |

Non-standard options are available upon request, including:

- Mesh height increase

- Steel lids

- Canvas tops

- Heel pin fixings

Dumping Hopper Conformity

These Dumping Hoppers comply with OSHA regulations and relevant US standards.

What is the difference between a Dumping Hopper - Heavy Duty & Forklift Self-Dumping Hoppers?

Heavy duty dumping hoppers are manufactured using 3/16" thick mild steel, whereas the Forklift Self-Dumping Hoppers are manufactured using 11-gauge mild steel. This makes the heavy-duty dumping hopper more durable. The forklift self-dumping hoppers have reinforced edges, that are folded back on themselves to give the hopper greater strength. This is not needed for the heavier-duty hopper, which has simple folded edges instead.

What is the difference between a Forklift Dumping Hopper & a Telehandler Dumping Hopper?

Our heavy-duty forklift dumping hoppers & forklift-self dumping hoppers are designed to be lifted and tipped using a forklift. They are fitted with safety chains secured to the forklift. They sit on a pivot and once the latch is released they roll forward emptying their contents. They are then self-righted and the latch secures them back into place.

In comparison, the telehandler dumping hopper is designed for telehandlers. There's no dumping mechanism, spring, or safety chain. Instead, the telehandler forks enter the hopper and the gas strut on the back locks it to the forks. Contents are emptied by the telehandler leaning forward. This means the operator never needs to leave their cab, reducing safety risks.

How wide are the fork pockets on the Forklift and Telehandler Dumping Hoppers?

The fork pockets on all our Forklift and Telehandler Dumping Hoppers are 5.5 in. wide, though we can make these 6.3 in. upon request. The spacing between the pockets is 36.2 in. (inner to inner), maximizing weight distribution and stability.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH